In the evolution of high-performance commercial building design, it's more important than ever to understand the role of the building enclosures. Since building and energy codes now require multiple continuous control layers to ensure and maintain building envelope integrity, the design of roof-to-wall transitions, in particular, presents unique challenges.

Poorly designed or executed transitions where various planes of the building enclosure intersect can potentially compromise water, air, thermal, and vapor control. This, in turn, can affect a building's energy performance, durability, and the health and well-being of its occupants.

Here's a look at some typical roof-to-wall transitions, like parapets, adjacent wall intersections, and low roof edges, and some strategies for maintaining the integrity of the key control layers within the building enclosure.

Overview of Control Layers

To understand the unique roofing challenges of roof-to-wall transitions, it's important to review the four key control layers, which should be continuous across all six sides of the building enclosure.

Water Control

The first line of defense against the infiltration of bulk water, such as rain or melting snow, is the roof membrane and the building cladding. In wall areas it is also often required by code to include a secondary water control layer, located within the assembly, either below or behind exterior finish and integrated with the roof and wall flashing.

Air Control

Air barriers help prevent outside air from entering a building and conditioned air from escaping, which can help improve energy efficiency and enhance indoor air quality. The air control layer at the roof can be located at the deck level; from there, it can transition vertically at the wall plane.

It's possible for the roof membrane to function as an air barrier, but the details—including wall transitions—must be managed carefully. Far more moisture can enter a building through gaps in air barriers than through vapor diffusion through building materials, so maintaining continuity of this control layer across the entire building enclosure is particularly important.

Thermal Control

Building insulation is a crucial part of the building enclosure, as it helps control heat transfer between the interior and exterior, thus minimizing heat loss in cold weather and heat gain in warm weather.

To be effective and code-compliant, insulation must be continuous and connected at all roof-to-wall transitions, which can be tricky. Common concerns include interruptions of continuity at the roof edges and the possibility of thermal bridging (and the resulting heat loss and condensation that can occur).

Vapor Control

A vapor-retarding membrane controls the diffusion of water vapor through building materials, such as insulation or concrete decks. It can occur in the same plane as the air control layer. In some cases, a vapor control layer can also act as an air barrier.

The necessity and location of a vapor control layer depend on building location, interior use, and building construction methodology. Due to the often contradictory or periodic nature of vapor drive direction across the building enclosure, it may be helpful to perform a hygrothermal analysis per ANSI/ASHRAE Standard 160 to determine if, and where, a vapor control layer is necessary.

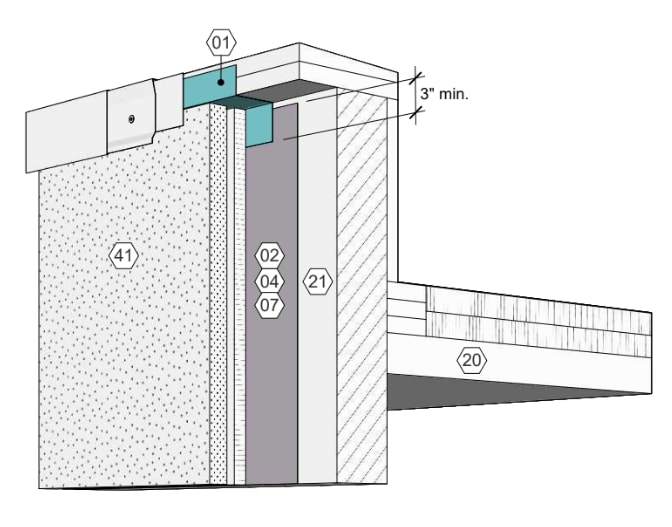

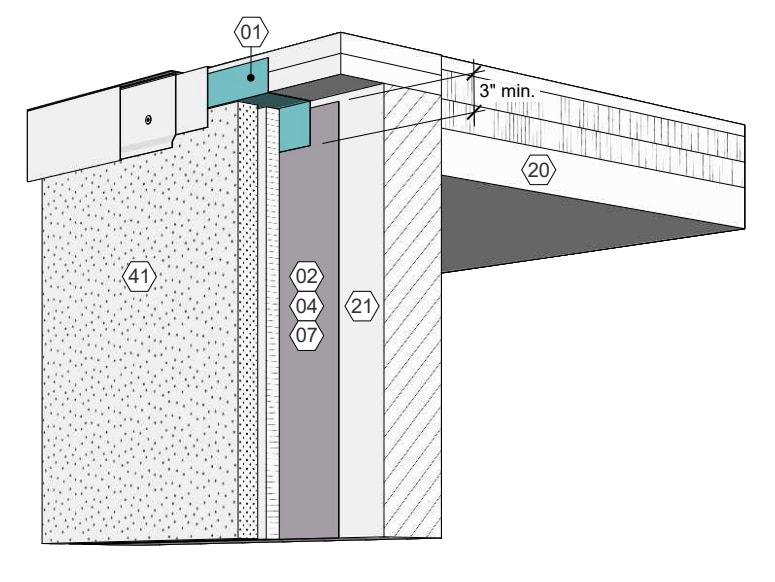

Detailing Parapets: Where Design and Weather Resistance Meet

Many commercial buildings with low-slope roofs incorporate parapets in their design. A parapet, which is an exterior wall above roof level, can protect and hide rooftop mechanical equipment, provide increased wind resistance and fall protection, and contribute to the design aesthetic of the building.

Common failures due to the unique roofing challenges of parapets include thermal bridging caused by interruptions in building insulation by exposed structural elements, water infiltration due to gaps in membranes or at coping joints, inadequate flashing/counterflashing, expansion and contraction of dissimilar adjacent materials, or condensation due to interruptions in air or vapor control layers.

Because control layers must be continuous at all sides of a building enclosure, including at roof-to-wall parapet transitions, construction details and specifications that address these conditions are particularly important. Standard details, or specifications that call for materials to be "or equal" or installed "by others," will not adequately address the unique design and construction challenges posed by most roof/parapet transitions.

It's possible that some critical details may be difficult to illustrate by 2D drawings alone and could require the use of exploded diagrams and/or specific sequencing instructions. The use of a "pen test"—in which each control layer is traced with a colored line to demonstrate continuity across the building enclosure—can be helpful during design as well as when communicating design intent in the field.

Another option for more complicated conditions is to construct full-scale mockups to demonstrate parapet details. Construction sequencing and vigilant coordination among the various trades are critical to ensure the proper installation and continuity of each control layer of the building enclosure.

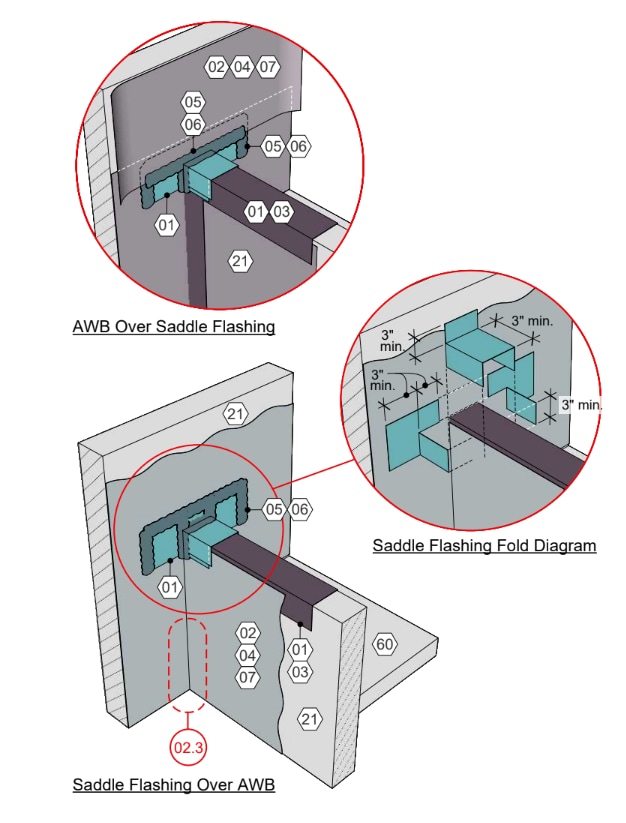

Adjacent Walls: Managing Complex Intersections

Transitions between roof planes and adjacent walls—especially involving parapets—also require careful sequencing and coordination. These conditions include walls that intersect the roof plane because of changes in roof height, parapet walls that terminate at an adjacent building wall, and building walls that intersect or extend beyond the parapet.

The unique design and construction challenges that can be present in these situations include discontinuous control layers at the juncture of horizontal and vertical planes, incompatible materials from one plane to the next, errors in construction sequencing that could create opportunities for air or water infiltration, and inadequate flashing at wall intersections, penetrations, or where building enclosure layers overlap.

Strategies similar to those recommended when detailing parapets are also useful in these circumstances, as well as considering the use of liquid membrane products to maintain continuity over dissimilar materials, complex geometries, or resolving sequence realities that may appear as counterflashed conditions. Specifying pre-manufactured detail accessories at penetrations, corners, and terminations can help reduce errors in field fabrication that could compromise the building enclosure.

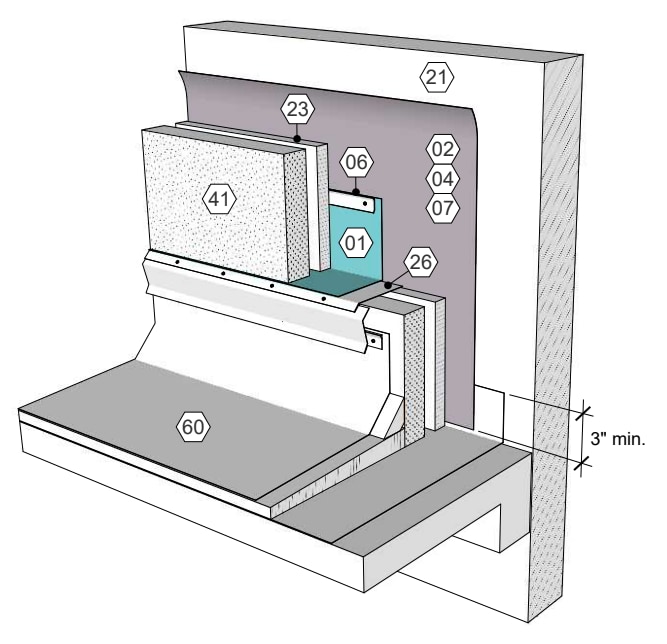

Low Edges and Transitions to Low-Slope Roofs

Low or flush roof edges to wall connections present their own unique design and construction challenges. They're susceptible to water accumulation, since water tends to pond at low points. Changes in roof elevation at transitions to a lower slope can disrupt the flow of bulk water and cause drainage issues. Solutions include using sealants, reinforced PMMA flashing liquid flashings, slightly elevating roof edges at transitions to divert water away, and paying particular attention to flashing at penetrations and terminations to ensure water-tightness.

The advantages of flush roof edges include the ability to wrap control layers over the edge and down the wall with less of the potential interruptions and coordination headaches of tall roof parapets. However, care needs to be taken at the coping to make sure fastener penetrations are sealed, and edge blocking does not interfere with layer continuity.

Simplifying the Roof-to-Wall Transition

Today's high-performance building enclosures demand meticulous planning, detailing, and coordination. It's recommended to engage a building enclosure professional when necessary and select products from a reputable manufacturer that offers a complete portfolio of solutions that are compatible across the entire building enclosure and provides design and construction phase support throughout the project.

These actions can help ensure successful integration of key control layers while meeting the sustainability, performance, and long-term durability goals of the building enclosure.

See Siplast Commercial Wall Solutions for products that can provide seamless integration at roof-to-wall transitions and contribute to successful building envelope design.

Diagram Footnote:

- Siplast WALLcontrol Stainless Steel Butyl Adhered Flashing

- Siplast WALLcontrol Reinforced Aluminum Butyl Adhered AWB

- Siplast WALLcontrol Reinforced Aluminum Butyl Adhered Flashing

- Siplast WALLcontrol Modified Silicone (STPE) VP Liquid AWB

- Siplast WALLcontrol Modified Silicone (STPE) VP Liquid Flashing

- Siplast PS-715 NS Elastomeric Sealant

- Siplast WALLcontrol Monolith VP Adhered AWB

20. Roof Structure

21. Wall Structure

23. Insulation

41. Wall Cladding

60. Roof or Waterproofing System