Producing a high-quality SBS-modified bitumen membrane is a precise material science process built on four critical stages: raw material selection, formulation, manufacturing, and quality control. These steps are essential for achieving advanced properties like ultimate elongation and resilience to cyclic environmental stress, ensuring the membrane's superior performance and durability by defining the specific functional role of every component.

The Key Materials in SBS-Modified Bitumen

A high-quality modified bitumen sheet begins with carefully selected materials. The following materials work together to define its physical and mechanical properties:

- High-Quality Bitumen: As the base material, the bitumen's final physical characteristics are determined by its original crude oil source and distillation process. Selecting a compatible crude oil source is critical, as the resulting bitumen must possess the correct chemical makeup (e.g., asphaltene and maltene content) to be successfully modified by SBS polymers; not all bitumens can be successfully modified.

- Filler: Inorganic minerals function as fillers to enhance blend stability and add fire-resistant properties to the material. However, the higher filler content can make the material more rigid and plastic-like rather than elastic, potentially compromising flexibility.

- SBS Polymer: Styrene-Butadiene-Styrene (SBS) polymers are added to provide rubber-like elastic properties, which enable the material to stretch when the roof expands and contracts because of temperature changes. The amount of polymer added to the blend depends on the desired softening point properties. The material maintains its elastic properties for extended periods because of high polymer content, which counteracts the natural aging process that causes bitumen to become brittle.

- Reinforcement: Reinforcement materials are crucial for several reasons: They facilitate the roll-to-roll manufacturing process, provide shape, stabilize the roll during shipment, and contribute mechanical properties beyond basic waterproofing. Reinforcements can be made of polyester, fiberglass, or a combination of both.

Inside the SBS Formulation Process

A high-performance SBS formulation is defined by superior materials: high-grade asphalt, a high percentage of premium polymers, and an optimal amount of filler for durability. The quality of both the new and aged membranes is determined by a precise asphalt-to-polymer ratio.

The necessary controlled batch blending ensures the optimal material formulation is achieved using continuous circulation and sieve mixers. These powerful mixers generate the high shear forces required to effectively swell and disperse the SBS polymer within the bitumen, forming a stable, elastic network. Precise thermal and mechanical controls throughout the process prevent polymer degradation, guaranteeing a high-quality membrane with superior durability and performance.

Manufacturing: Translating Formulation Into Membrane Performance

Manufacturing brings the formulation into its final sheet form. Reinforcements are combined with the SBS blend using roll-to-roll production methods that ensure consistent thickness, adhesion, and membrane structure. Proper control during this stage preserves the elastic properties developed during blending and ensures reliable mechanical performance in the finished sheet.

Quality Control: Ensuring Consistency and Performance

Last but not least is the quality control process, which sets the standard for SBS modified bitumen membranes. Rigorous testing on the blend every hour and a half to ensure consistency and achieve desired properties is necessary for a high-quality membrane. Then a dedicated quality control team tests the finished product on the line to ensure it meets the dimension specifications.

Testing for Key Performance Properties: Why SBS Stands Apart

The two critical performance characteristics of SBS-modified bitumen systems are ultimate elongation and cyclic fatigue resistance, which determine their effectiveness and the longevity of the product.

Ultimate Elongation

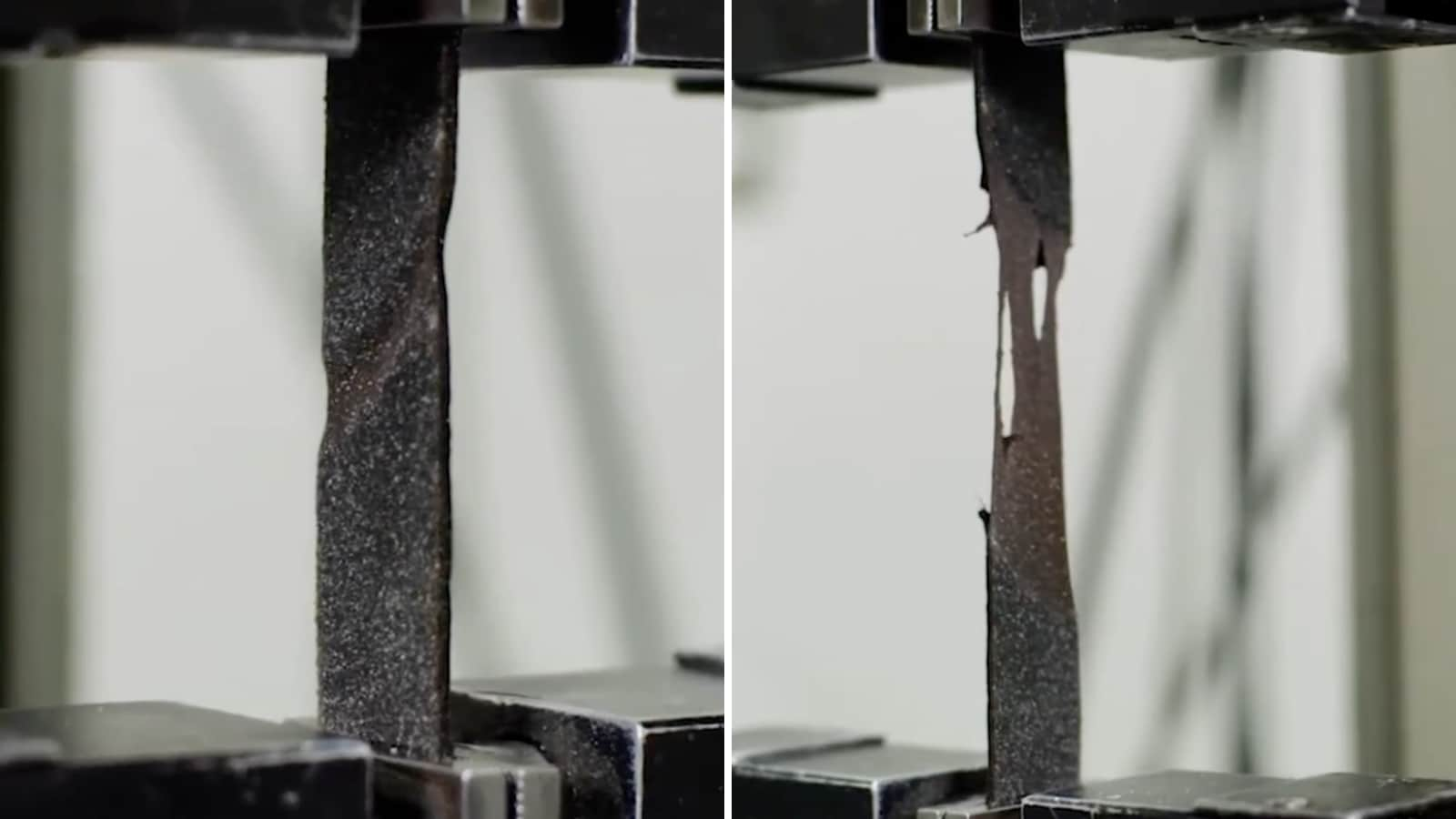

Ultimate elongation refers to the ability of the SBS-modified bitumen blend to stretch significantly, even after the reinforcement within the membrane has broken. This property provides a critical water-tight reserve.

The evaluation of ultimate elongation at peak load becomes more meaningful when considering the ASTM testing standards for SBS-modified bitumen sheets. The ASTM standards D6162, D6163, and D6164 establish the testing requirements.

The testing standards require measurements of "elongation at peak load" at temperatures of 0°F and 73°F. The test procedure involves stretching a sheet sample until the reinforcement reaches its breaking point at peak load while recording both the force measurement and percentage elongation at that instant. The majority of SBS sheets experience breakage shortly after their reinforcement material reaches its yield point.

High-quality SBS blends used in Siplast Paradiene sheets demonstrate extended stretching ability after the reinforcement fails. High-performance sheets demonstrate exceptional ultimate elongation by stretching up to 240% after the reinforcement breaks at 56–57% elongation. The extra 83% elongation after peak load provides substantial waterproofing protection.

Material composition determines the maximum amount of elongation a material can achieve. The testing results demonstrate that products containing more fillers and fewer polymers exhibit reduced blend elongation and increased rigidity. The aging process of bitumen leads to oxidation, which makes it more brittle, but sufficient polymer content in the formulation prevents this degradation from affecting elongation properties. The assessment of elastic properties depends on measuring elastic modulus values that need to stay within specific limits.

Cyclic Fatigue Resistance

The roof membrane experiences continuous movement because of temperature fluctuations, which cause the membrane to expand and shrink throughout the day and across seasons. The ability of modified bitumen membranes to handle multiple cycles of movement or displacement defines their cyclic fatigue resistance.

ASTM D5849 serves as the standard test method for assessing modified bitumen roofing membrane cyclic fatigue resistance through joint displacement testing. The test procedure requires a modified bitumen system consisting of a base and cap sheet to be attached to a substrate with a small gap, which then experiences repeated movements between separation and reunion while stretching the membrane above the gap.

The results of cyclic fatigue tests demonstrate that SBS-modified bitumen sheets from different manufacturers show various levels of performance. The Siplast Paradiene 20/30 system achieved excellent results during ASTM D5849 testing, according to a study conducted by Siplast. The test results showed that only the Siplast Paradiene 20/30 system met the requirements for new membrane standards, while another non-Siplast SBS modified bitumen sheet failed to meet the requirements for aged membranes.

The testing results show that ASTM standards enforce physical requirements, but cyclic fatigue testing remains optional for SBS standards, which creates a major performance distinction between products.

Material Performance in the Field

The advanced material science behind high-quality SBS-modified bitumen can directly translate to tangible benefits for roofing systems, particularly in terms of durability and reduced maintenance needs.

The properties of ultimate elongation and cyclic fatigue resistance contribute significantly to the practical performance of roof systems, which include:

- Greater Durability: Systems formulated with superior SBS-modified bitumen can achieve greater durability, potentially achieving a 30–40-year system service life.

- Reduced Repairs and Membrane Failure: The inherent elasticity and resilience help minimize the need for repairs and reduce the risk of membrane failure. Even if the reinforcement within the membrane breaks, a high-quality SBS blend can maintain its integrity as a waterproofing layer for a period, offering a crucial buffer until repairs can be made.

- Suitability for Institutional and Long-Hold Assets: Given their enhanced durability and reliability, SBS-modified bitumen systems are particularly suitable for institutional and long-hold assets, where long-term performance and minimal disruption are paramount.

Differentiating SBS Membranes: Not All Are Equal

It's important for specifiers and building owners to recognize that not all SBS-modified bitumen membranes are created equal. The general classification of these membranes hides major differences between their formulation and performance characteristics.

For example, the physical requirements for cyclic fatigue testing do not apply to all ASTM standards that govern SBS products. Some products that fulfill ASTM standards may not provide the same level of resistance to roof movement and stress during their extended service life.

The Siplast-commissioned study demonstrates that different manufacturers' SBS-modified bitumen systems exhibit distinct performance levels when subjected to cyclic fatigue testing. The selection process for roofing materials should focus on properties exceeding minimum ASTM standards to achieve durable and long-lasting roofing solutions.

The Science Behind Long-Term Roof Performance

The long-term performance of roofs depends on material science factors, which include selecting raw materials and following exact manufacturing procedures for SBS-modified bitumen systems. The two essential properties of membrane performance in dynamic roof conditions are ultimate elongation and cyclic fatigue resistance. The selection of high-performance roofing materials becomes more effective through understanding the distinct methods of achieving and testing these properties.

A building's long-term roofing needs and physical requirements should be included in specifications to obtain a roof system with high performance and extended lifespan. The Siplast Paradiene 20/30 membrane system fulfills strict performance requirements for ultimate elongation and cyclic fatigue, which makes it suitable for protecting critical building assets.