Siplast arguably makes the leading SBS-modified bitumen membranes in the roofing market. This is something that Siplast has been doing for decades-–quietly leading the industry with excellent products, and top-notch field assistance and customer service.

Siplast essentially invented the SBS-modified bitumen roofing membrane. First, some history. Siplast S.A. was established in 1955, and shortly after, in 1958, Siplast introduced the first high-performance foil-clad roofing product – Veral. Veral is still on the market today and continues to perform well.

The SBS-modified bitumen breakthrough came in the mid-to-late 1960s when Siplast and Shell Chemical developed the styrene-butadiene-styrene asphalt blend. (SBS is synthetic rubber.) The development of the SBS-modified asphalt blend immediately led to the introduction of Siplast's Paradiene® base sheet and cap sheet membranes. This was all happening in Europe; France, to be exact. And then in 1979, Siplast started doing business in the US on an import basis. The plant in Arkadelphia, AR, was built, and production in Arkansas began in 1981 and continues in Arkansas today.

A key factor in locating the Siplast manufacturing plant in Arkadelphia is the proximity to a high-quality source of bitumen. The Smackover oil field–in southwestern Arkansas and northeastern Texas–has been a petroleum source since the 1920s. Siplast has been using asphalt that is derived from refining crude oil from the Smackover oil field since our manufacturing began in the U.S. in 1981. Using a single source of asphalt throughout its U.S. history, Siplast has been able to create a consistent and reliable high-performance asphalt blend.

The history and location of the plant are important because a consistent, single-source of asphalt lends itself to key physical properties. That, with a commitment to quality, helps ensure the highest quality SBS-modified bitumen sheets are manufactured. So what exactly sets Siplast apart? It's our commitment to producing the highest quality SBS-modified bitumen sheets on the market.

Certificate of Analysis

A roof requires 4 key ingredients – high-quality products, thoughtful specifications, quality application, and responsible maintenance – to achieve a long service life. The owner has the ability to control the quality of the specifications and the application, as well as take responsibility for maintenance. Of course, the specifications can be written around a superior membrane, but how does an owner get assurances of quality?

Siplast's commitment to quality is shown in its commitment to quality control. Siplast's Certificate of Analysis (CoA) documents are the result of stringent quality control tests performed on a specific lot of material.

The values reported on each CoA are not an average of a laboratory study performed once a year. Rather, the values shown are the actual data taken as a matter of routine quality control practiced each and every day.

Why do we do this level of analysis? First, and most importantly, Siplast has great confidence in the consistent quality of the products that we manufacture and supply to our customers. Second, as a result of our routine testing of competitors' products, we are convinced that product quality varies widely among competitors. Further, it has been our experience that the quality of some manufacturers' products is inconsistent from one production run to another. Showing the consistency of our product for all of our production runs validates our commitment to quality.

A Siplast CoA contains three sections of information: Product Identification, Dimensions and Mass, and Physical and Mechanical Properties. The Product Identification section provides the commercial name of the product, the run date, and item and lot numbers. The Dimensions and Mass section provides data about length, width, thickness at selvage, total thickness, weight, and selvage width. The Physical and Mechanical Properties section provides data about low temperature flexibility, granule embedment, breaking load, ultimate elongation, compound stability, and when appropriate for the material type, dimensional stability and resistance to thermal shock. Siplast CoAs are available upon request.

More information about Siplast's Certificates of Analysis can be found here.

Right to Test During Installation

Siplast will supply a Certificate of Analysis (CoA), and Siplast has no problem if our SBS sheets are sampled and tested during installation. Our frequent in-plant quality control procedures help us ensure that only products that meet the minimum ASTM requirements and our internal minimum requirements receive a label and are shipped for use. It's really that simple–Siplast believes in the product that is shipped, and Siplast welcomes verification of the quality of our products.

Siplast's RoofTag program combines the Certificate of Analysis with on-site physical-property verification. RoofTag is an RF technology that uses RF chips that are embedded in Siplast SBS membranes. Scanning a RoofTag provides access to the CoA and product information. Comparing test results from membranes that are sampled and tested during installation to CoA information discoverable via RoofTag provides an extra measure of assurance of Siplast quality. RoofTag and CoAs are tools Siplast provides to help consultants and owners with roof asset management.

More information about Siplast's RoofTag program can be found here.

Ultimate Elongation

SBS modified bitumen sheets are tested to determine their Elongation at Peak Load. This test determines the amount a modified bitumen sheet stretches (or elongates) when the reinforcement breaks. When the reinforcement breaks, the load (aka, the peak load) and percent elongation of the sheet are recorded. However, when the reinforcement breaks, the blend – the asphalt – does not break because it is elastic.

For high performance SBS modified bitumen sheets, the blend will continue to stretch and not break. In the graphic below, the polyester reinforcement breaks at approximately 56-57%, yet the blend is still intact. The blend continues to stretch upwards of 225% until it breaks. This is deemed Ultimate Elongation. Ultimate Elongation indicates the elasticity of the blend. The asphalt blend should stretch (or elongate) 30 to 50+% beyond when the reinforcement breaks. If the blend breaks shortly after the reinforcement breaks, the ability of the sheet to perform as a waterproofing layer may be compromised.

This graph shows a high-performing Siplast Paradiene SBS-modified bitumen sheet that also has very high Ultimate Elongation.

A high Ultimate Elongation can help provide a watertight 'reserve' if the reinforcement were to break. However, roofs often need the ability to withstand repeated cycles of movement. Realize that roofs do in fact move due to thermal changes that occur from summer to winter that can expand and contract a roof membrane. Perhaps more critical are the daily temperature swings that can also cause significant movement. To that end, let's talk about another property of the membrane – cyclic fatigue.

Cyclic Fatigue

Continued small-scale cyclic displacement of a roofing membrane can cause cyclic fatigue. Even without true moving parts, roof membranes move due to thermal expansion and contraction. Most often this movement is small, but at critical locations, such as a stripping ply at edge metal.

Cyclic fatigue of roofing membranes is tested according to ASTM D5849. To run the D5849 test, a modified bitumen system (i.e., a base sheet and a cap sheet) is adhered to a substrate that has a small 2mm gap. The substrate moves apart (to 3mm) and together (to 1 mm) for a large number of cycles. This stresses (that is, fatigues) the SBS modified bitumen system just above the small gap. Comparison testing of Siplast competitors showed only Siplast and one other met the 500-cycle requirement for new membranes, and no other competitor met the 200-cycle requirement for aged membranes. If a competing manufacturer claims to meet the 500- and 200-cycle cyclic fatigue testing, ask for data!

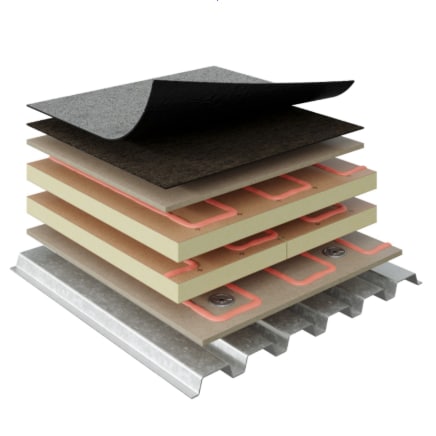

Because Siplast strongly believes cyclic fatigue is a key characteristic to long term performance, Siplast's 2-ply Paradiene 20/30 system was, and still is, designed to take the stresses from the substrate and stresses from the exterior. The plies are designed to work together. The Siplast 2-ply SBS membrane system is designed to prevent cyclic fatigue. Specifically, the base ply absorbs approximately 80% of the stresses from substrate movement, and the top ply protects against heat, cold, UV, physical abuse, degradation from O2, and water (in its many forms).

Read more about Ultimate Elongation and Cyclic Fatigue in this White Paper.

Encompass Program

As stated earlier, a roof requires 4 key ingredients – high quality products, thoughtful specifications, quality application, and responsible maintenance – to achieve a long service life. Arguably, the most overlooked of the four is responsible maintenance. Roofs are often "out of sight, out of mind." And with no moving parts, what's to maintain? Roofs, in fact, do move. Roof temperatures can vary significantly from the heat of summer to the cold of winter. Expansion and contraction happens over the course of a year, and can occur over the course of a single day with varying temperatures and climatic conditions.

What are some of the other common things that can cause a roof to wear out or experience damage?

Exposure to air pollutants, building operational emissions, and chemical deposits

Structural movement

Standing water

Biological contaminants including vegetation, algae, dust, and dirt

Equipment additions that are improperly flashed or weatherproofed

Trade damage from non-roofing professionals

To assist owners in keeping up with maintenance, Siplast has the Encompass Program. The Siplast Encompass Program enables development of a roof maintenance plan for new or existing Siplast roofing and waterproofing systems that is tailored to the owner's needs.

A customized Encompass program may include:

Periodic roof inspections with photographic report on existing conditions

Infrared roof analysis of insulated roof constructions to identify thermal anomalies

Electronic Field Vector Mapping (EFVM) to locate any actual breach in the membrane system

Non-destructive tests to determine potential moisture contamination or other such conditions

General preventive roof maintenance functions

Other services appropriate for the project type and conditions

Participation in the Encompass Program provides an opportunity for uninterrupted guarantee extensions, as well. More information about Siplast's Encompass Program is available in this brochure.

What sets Siplast apart from the competition is blend quality, our unwavering allowance of testing of our products during installation, cyclic fatigue, ultimate elongation, and our outstanding quality control and the associated Certificates of Analysis.

Prove it to yourself. Touch and feel our products. Then get a hold of our competition's products. You will be able to feel the suppleness and flexibility of our high-performance SBS-modified bitumen sheets.