Ben Meyer, Building Enclosures Roofing Director at Siplast, has been building bigger from day one. As a kid playing with LEGO sets, "I would build things, tear them down, build something else—always something new," he says.

That's just the way his brain works. "I like to build things," he explains. "I make things for fun. That's what I do." That curiosity led Ben to become a highly specialized industry leader in building enclosure.

Today, that constructive drive is helping Siplast build out the offerings of Siplast by expanding product lines and technologies to better support partners every step of the way. His small but mighty team recently launched Siplast's first full above-grade air and water barrier system, and they're "working diligently on getting the below-grade, waterproofing, and walls." All while continuing to evolve solutions to meet the unique needs of customers in specific regions and markets.

Ben's Educational Journey

Ben's journey began in Ohio, where his hands-on drive laid the foundation for his future career. In high school, he immersed himself in physical labor rooted in problem solving, machine operation, and installing HVAC systems. Due to his love for how things go together, Ben initially pursued mechanical engineering, but he found the repetitive nature didn't satisfy his inherent curiosity.

"I was good at math, but doing the same math problem over and over again wasn't very rewarding," he says. He decided, "I'm going to try architecture. It might scratch the itch a little better - asking more questions, digging a little deeper, understanding the 'why' of solving complex problems."

At the University of Cincinnati, Ben participated in a robust co-op program that allowed him to alternate between classroom learning and real-world experience every other quarter for six years. By the time he earned his three degrees (a Bachelor of Science in Architecture, Master of Architecture, and Master of Business Administration), he'd gotten plenty of hands-on experience through multiple internships.

From Design-Build to Building Enclosures

After graduation, Ben gravitated toward design-build firms where he could see projects from initial design through construction. As a Project Manager at Bloomfield/Schon + Partners, Ben deepened his talent for problem-solving and seeing projects through to completion.

Ben's journey into building enclosures was fortuitous but also a natural progression that built on his understanding of wall claddings, air and water barriers, and managing increasingly complex projects. He recognized the strategic importance of the building envelope early on.

"Most of the money goes into the outside of the building," he emphasizes, highlighting the critical financial and operational implications of enclosure design. He spent considerable time optimizing high-end finishes, claddings, and windows within budget constraints, demonstrating an early "passion or a bend toward building enclosures." He describes himself as "much more of a technical architect" who enjoys the details.

"The recession in Ohio was a pivot point for me," he says. He'd just finalized his architecture license process, but job prospects were declining, and at the same time, from a real estate development perspective, bank lending was very limited.

Seeing an opportunity, Ben pivoted to construction administration with a manufacturing focus. He took a job with DuPont as a Construction Project Manager, where he focused on large capital projects in a role that included general contracting, owner's representative. "I built a Kevlar plant, a Mylar plant, and a sulfuric acid plant. There was a lot of really heavy industrial construction."

At DuPont, Ben transitioned from managing capital projects to support the Tyvek commercial enclosure business as the Building Science & Sustainability Leader, working closely with designers, owners, and contractors. His proactive engagement in industry committees and standards bodies during this period was pivotal, positioning him as a recognized expert in building science, air and water barriers, and commercial codes. His service included roles as a Full Committee and Envelope Subcommittee voting member for the Air Barrier Association of America and ASHRAE Standard 90.1 as well as a Project Committee member for ASHRAE Standard 189.1.

Transition to GAF and Siplast Leadership

Ben's transition to GAF came naturally after a period of consulting with ECS Limited. When Jennifer Keegan, a colleague at Siplast and GAF, posted a role that "seemed too on the nose to be for anyone else," he knew it was the right fit. As Building & Roofing Science Architect at GAF from August 2019 to August 2021, Ben focused on education and advocacy, helping architects and consultants navigate building codes and material specifications.

His move to Siplast in August 2021 as Building Enclosure Business Director, North America, represented more than just a new title—it was a chance to drive strategic innovation. Historically focused on roofing and horizontal waterproofing, Siplast brought Ben on board to expand the product portfolio. "My goal has been to essentially fill out our portfolio to help Siplast become a leader in full building enclosure solutions," he explains.

His approach was deliberately customer-centric. "My first months were about listening. I wanted to know exactly what customers loved about Siplast and then identify opportunities beyond our existing offerings."

Through extensive conversations with clients, Ben uncovered specific gaps in the market, and these insights led to tangible innovations, like the recently launched Siplast WALLcontrol™ Monolith VP. Designed to overcome the limitations of traditional fleece-based vapor-permeable barriers, WALLcontrol™ Monolith VP reflects Ben's ability to anticipate industry needs and deliver practical solutions.

"We saw an opportunity to create a vapor-permeable product that eliminates the need for fleece," he says. "It's a solid film that resists air and water penetration while enabling trapped moisture to escape, without compromising adhesion, UV resistance, or compatibility with sealants." The innovation is particularly effective at resisting wetting during construction, especially in moisture-sensitive climates, like the Pacific Northwest.

Internally, Ben describes his division as "a startup business within a large corporation," emphasizing the agility and innovation of a lean, cross-functional team. He works closely with marketing, R&D, sales, and technical support to ensure every new product is fully integrated, from concept to customer success.

Leadership with Vision: Shaping the Future of Building Science

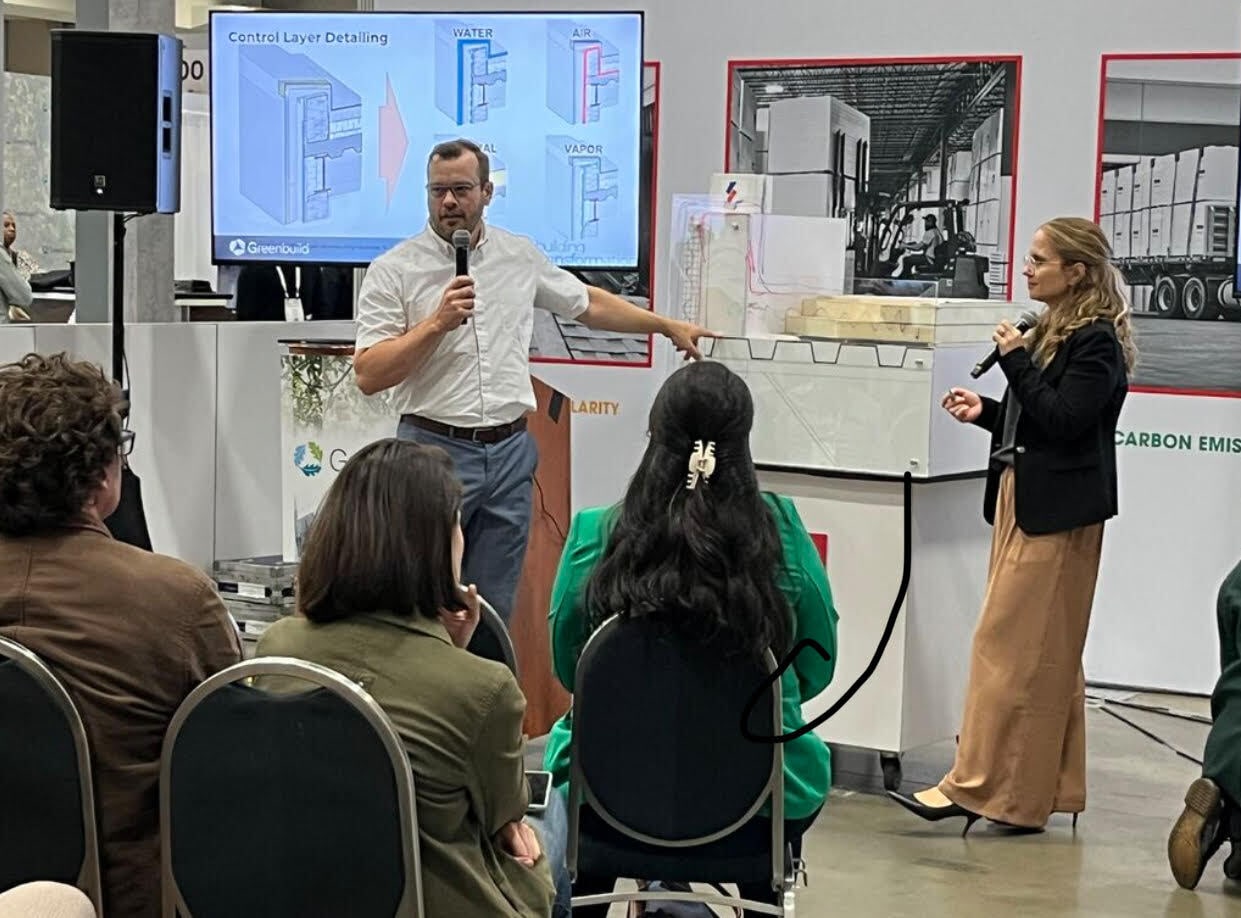

Beyond product development, Ben remains deeply committed to advancing the building enclosure industry as a whole. His extensive committee involvement, including ongoing Chair of the Envelope Subcommitee with ASHRAE Standard 90.1 (January 2013–present), his role as a Director for the Air Barrier Association of America (January 2013–2025), and his tenure as a Technical Committee Member for the U.S. Green Building Council (January 2019–January 2023), has directly influenced energy efficiency codes and sustainability standards across the industry.

Ben's career reflects a steadfast belief in continuous learning and intellectual curiosity. He emphasizes the importance of understanding the "why" behind every product to help authentically solve customer challenges.

For those considering a career in building science, Ben offers candid advice: "Nobody goes to school to do building enclosures. There's a certain group of people who gravitate toward it—people who ask a lot of questions, who are genuinely curious, and who want to understand how things work," he says. "If someone's the type who just wants to check a box and move on, they're probably not a building enclosure person."

While no one starts as a "wall person," as Ben puts it, curiosity is essential: "You have to be curious enough to dig into it. Every building is different. You can't assume you know the answer." That mindset continues to shape Ben's work at Siplast, where his vision centers on driving innovation, upholding rigorous technical standards, and empowering clients through practical support and education.

From building with LEGO sets in Ohio to pioneering advanced enclosure solutions across North America, Ben Meyer's path exemplifies how passion, practicality, and relentless curiosity can fuel meaningful industry progress. At Siplast, he's not just developing products—he's building the future.