This article was written by Jim Kirby, AIA in partnership with Rick Kile, RLA, CDT, GRP

Hot-rubberized asphalt (HRA) membranes have been used in the waterproofing industry dating back to the 50s, when it was originally used as a slit slab waterproofing material. Hot-applied systems are fast-setting- without any chemical cure process, adhered directly to the substrate, and monolithic (i.e., seamless). HRA membranes are often used as a waterproofing membrane over concrete decks with overburden, such as vegetated roof systems and amenity decks, or in split-slab construction.

HRA Membrane Components

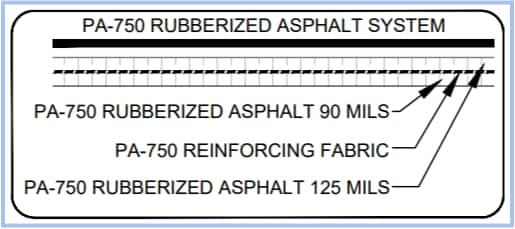

A traditional HRA system consists of a base layer of hot-applied rubberized asphalt applied at 90 mils, a reinforcing fabric embedded into the base layer of rubberized asphalt, and a top layer of hot-applied rubberized asphalt of 125 mils, followed by an asphaltic protection course. See Figure 1. As with all types of waterproofing systems, the use of appropriate flashing details is critical for long-term performance. Considering that an HRA itself is not UV stable, proper details using appropriate flashing materials, installed correctly, is critical to long-term success.

Figure 1: A graphic showing the components of a hot-applied rubberized asphalt (HRA) membrane, specifically Siplast's HRA membrane, PA-750. The PA-750 membrane consists of a base layer of hot-applied rubberized asphalt applied at 90 mils, a reinforcing fabric embedded into the base layer of asphalt, and a top layer of hot-applied rubberized asphalt of 125 mils, followed by an asphaltic protection course.

HRA Flashing Options

Within the waterproofing industry, there are a number of materials and methods that are commonly used to flash an HRA system.

HRA (same as the field membrane)

Modified bitumen membranes

Liquid-applied PMMA

Neoprene flashing membranes

HRA used as Flashing

Originally, HRA was the single method used to flash an HRA waterproofing membrane. Like other flashing methods discussed in this article, HRA-based flashings are installed prior to the application of the field of the waterproofing membrane. An HRA-based flashing uses the same installation method as is used with the HRA in the field of the roof–asphalt, reinforcement, asphalt. In other words, a first layer of hot-rubberized asphalt is applied on the horizontal and vertical, a reinforcement is embedded in the horizontal and turned vertically, and a second application of hot-rubberized asphalt is applied over the reinforcement, again horizontally and vertically. The field waterproofing is installed over the horizontal portion of the flashing, most commonly on the same day. HRA flashings are installed at least 8 inches vertically and covered with a protection layer to prevent physical damage during and after construction. Where the HRA base flashing is exposed to UV, it is critical to cover it with a UV stable product. Granulated modified bitumens and PMMAs are popular choices.

A key concern with HRA-based flashings is that they do not provide the durability of SBS-based flashings or PMMA-based flashings. The transition from horizontal to vertical is not constructed with multi-layered robust membranes or materials. Single-layer, pre-manufactured rubberized asphaltic flashing membranes can be used in lieu of hot-rubberized, site-built flashing installations. However, the pre-manufactured flashing sheet does not provide significant additional protection, as the construction is essentially equivalent to the field HRA application. In other words, field-constructed HRA-based flashing details used with HRA waterproofing membranes are not considered to be as durable in the areas that are typically found to be potential leak locations - transitions from horizontal to vertical and penetrations.

Modified Bitumen Membranes Used as Flashing

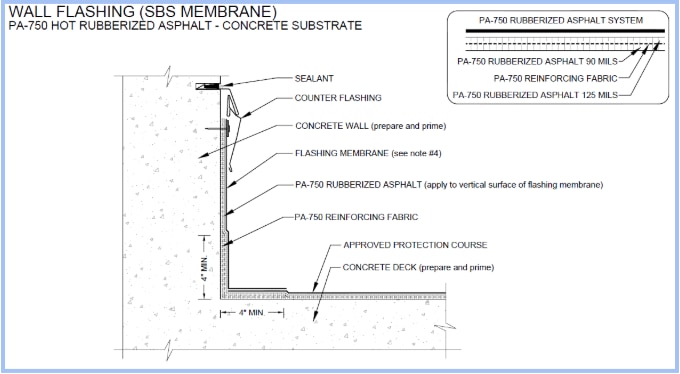

Modified bitumen membranes are popular choices for flashings used with HRA membranes. Modified bitumen membranes are naturally compatible with hot rubberized asphalt, and remain a cost-effective option. Details for HRA systems, such as curb and wall details, include an HRA membrane (3 course) installed first with a layer of modified bitumen membrane over the HRA. Many types of modified bitumen membranes can be used as flashings; granule surfaced and foil-faced membranes are common because of their durability and toughness,

The HRA flashing material is reinforced at the horizontal-to-vertical transition with the manufacturer's required reinforcing material at least 4 inches vertically and 4 inches horizontally. See Figure 2. Importantly, the HRA membrane should not be exposed to UV. Depending on the flashing configuration and overburden, the vertical portion of the HRA membrane may need to be covered, so it is protected from UV as well as physical damage. The protection layer may consist of sheet metal, and it should extend from the two-part counterflashing to a point below the top of the overburden.

High quality, robust SBS-modified membranes, such as Siplast's foil-faced Veral, and Siplast's granule-surfaced Parafor 30 and Parafor 50, are long-term solutions for HRA flashing installations and can provide the requisite UV protection in base flashing conditions.

Figure 2: A graphic showing HRA membrane with SBS flashing at a wall

Again, modified bitumen and HRA are highly compatible materials, and as such, modified bitumen flashings can be a long-term performance solution for an HRA waterproofing project.

Liquid-applied PMMA Used as Flashing

Polymethyl methacrylate (PMMA) is a polymer used as the primary component of liquid-applied membrane flashings used with roofing and waterproofing systems. PMMA flashings are two-component, fast-curing, durable, and chemically resistant. For more information about PMMA, visit https://www.siplast.com/education/pmma-roofing.

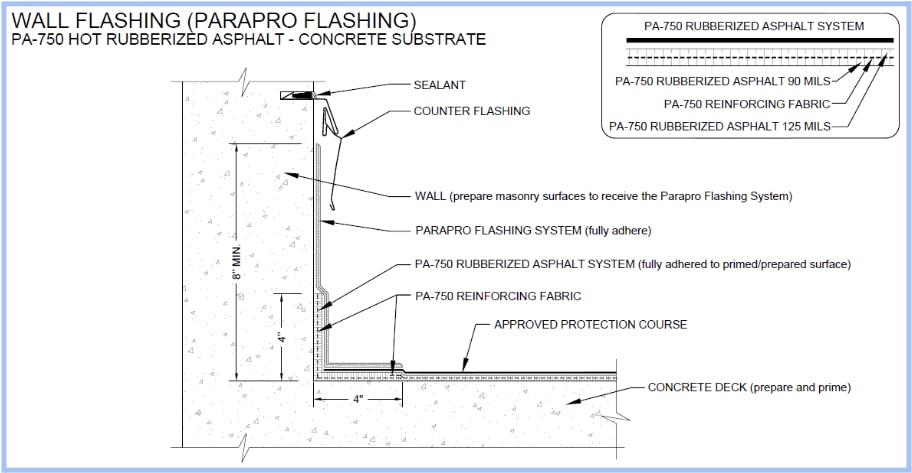

Typical HRA details that include PMMA flashings include HRA installed prior to the PMMA. The HRA is installed at the transition from horizontal to vertical using an 8 inch reinforcing fabric installed vertically 4 inches and horizontally 4 inches. The PMMA flashing system is installed over the transition and vertically at least 8 inches. See Figure 3.

The PMMA flashing is installed in a 3-step process. A base layer of PMMA is applied by brush or roller, a polyester fabric reinforcement is embedded in the PMMA base layer, and a top layer of PMMA is applied over the reinforcement. An example of a 3-step PMMA flashing is Siplast's Parapro 123 Flashing Membrane. Importantly, the PMMA does not need to be covered; it is designed for long-term UV exposure. As with all waterproofing flashing applications, a protection layer may be desired to protect from physical damage during and after construction.

Figure 3: A graphic showing HRA membrane with PMMA flashing at a wall

Siplast has been using PMMA as a flashing material for SBS roofing membranes for over two decades because of its compatibility with asphalt. The use of PMMA as a flashing material for HRA waterproofing projects is a clear choice because of the material compatibility and each of the product's long-term durability.

Neoprene used as Flashing

Neoprene is another technology that has historically been utilized as a base flashing in hot rubberized asphalt systems. A layer of HRA is applied to the substrate, and, commonly, a neoprene sheet is embedded into the HRA on the horizontal approximately 2 to 3 inches and vertically approximately 8 inches. The HRA acts as an adhesive to secure the neoprene sheet to the substrate. Where movement is expected (e.g., at a cold joint), a 6-inch wide strip of neoprene can be installed to provide more durability.

Neoprene is UV-stable and may be reinforced or unreinforced. A protection layer is typically used to protect the flashing installation from physical damage.

There are a number of concerns with the use of neoprene as a flashing material with HRA systems.

There have been occurrences that the uncured neoprene sheet starts to cure prior to installation. A cured neoprene sheet will not bond well with the hot rubberized asphalt; the result is a flashing sheet that is unbonded to the HRA during service.

Chloroprene is used to manufacture neoprene. According to Earth911.com, "neoprene is chemically inert, yet chloroprene is a carcinogen that can be inhaled or enter the human body through the skin. Choloprene is a persistent, organic-pollutant source material for neoprene. As a result, neoprene may not be suitable for projects with tight tolerances for sustainable and healthy building construction."

Neoprene never fully bonds to the membrane at a molecular level. In some forensic investigations, neoprene has been shown to "separate" from the HRA within the assembly.

For these reasons, Siplast does not support the use of uncured neoprene in our PA-750 system.

Conclusion

HRA waterproofing systems have been used successfully for a very long time. Over myriad years of use, manufacturers have incorporated different materials into the construction of flashings. Siplast is of the opinion that robust, multi-ply flashing installations, such as flashing details using SBS and PMMA, will lead to long-lasting, high-performing waterproofing systems.

For more information about Siplast's HRA products, visit our website: Siplast HRA