Waterproofing membranes help protect structures from water damage by creating a barrier against water infiltration. This makes them ideal for applications that involve higher levels of moisture due to environmental conditions or the presence of water, such as foundations, parking garages, and green roofs.

Discover more about how waterproofing membranes work, including their key applications, installation best practices, and performance benefits.

Key Waterproofing Applications

Waterproofing membranes are used in various applications across commercial and residential projects. Here are some key areas where waterproofing membranes are essential.

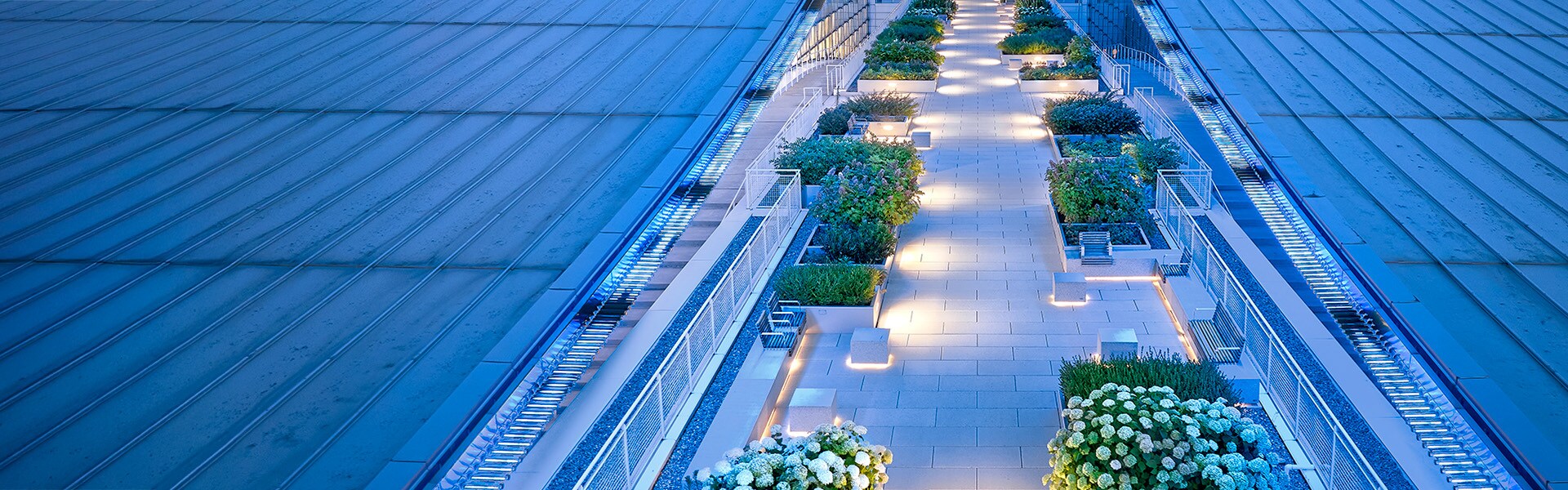

1. Waterproofing for Overburden Applications

Waterproofing for overburden applications pertains to the membrane that is installed atop the structure, but beneath any systems that may sit on top of the structure, to protect the space below. The overburden application may consist of vegetated roofs, amenity spaces, stormwater management systems, and more, where the membrane is buried and subject to the weight of the overburden systems and potentially consistently wet conditions. This application is most common in green roofs or amenity spaces, where the membrane must endure the weight of soil, vegetation, and water.

Keep in mind that both roofing and waterproofing membranes both play key roles in rooftop overburden systems. Roofing membranes are designed to shed water but aren't built to withstand prolonged ponding, soil contact, or hydrostatic pressure. Waterproofing membranes, however, provide critical protection in high-moisture environments—such as below-grade areas or under vehicular traffic—by keeping structures watertight even under constant water exposure.

Design considerations include ensuring the membrane can withstand the dynamic forces and stresses caused by these overburdened layers. Amenity spaces need to withstand the load of the objects and people using the space. Although drainage layers are commonly integrated into overburden systems, and it is good practice to provide continuous drainage, waterproofing membranes are selected for these applications because of their ability to hold water without issue.

2. Pedestrian Traffic Waterproofing

Pedestrian traffic areas, such as walkways and plazas, require waterproofing systems to handle foot traffic without damage. Here, the membrane should protect underlying structures from moisture while being durable enough to support the movement of people.

Pedestrian traffic waterproofing membranes are often designed to withstand abrasion, ultraviolet (UV) exposure, and other impacts. Surface finishes may also need to be specified to provide a slip-resistant walking surface.

3. Vehicular Traffic Waterproofing

Since many of them are exposed, parking garages and traffic decks need membranes that can withstand heavy loads of vehicles, water, and other environmental conditions to help ensure long-term durability and prevent structural damage. They often must also be resistant to chemicals, like oils, greases, and de-icing salts commonly found in parking structures.

4. Below-Grade Waterproofing

Foundations, basements, retaining walls, and other below-grade areas are prone to moisture infiltration. In these applications, waterproofing membranes must resist hydrostatic pressure and prevent water infiltration to prevent mold growth and structural degradation.

Designing for below-grade waterproofing requires attention to substrate preparation, including making sure the soil is properly compacted and that the membrane can bond effectively to the surface. The waterproofing membrane can either be applied after concrete foundations are placed (post-applied)) or before the foundation is placed(pre-applied), depending on project sequencing needs.

Waterproofing Membrane Types and Systems

There are several types of waterproofing membrane systems available to meet specific project needs.

For example, polymethyl methacrylate (PMMA) is a fast-curing, liquid-applied membrane ideal for both pedestrian and vehicular traffic applications. It can be adhered to various substrates and provides a durable, seamless waterproofing solution. PMMA waterproofing systems are particularly beneficial in areas with complex details, tight spaces, and multiple penetrations. Some PMMA systems are specifically designed to withstand the heavy stresses of vehicular traffic, providing a robust waterproof barrier while supporting the wear and tear associated with high traffic loads.

SBS-modified bitumen waterproofing membranes, such as Teranap®, initially designed for roofing, have become a viable option for waterproofing applications. These membranes are highly durable and typically used for pedestrian traffic applications, overburden, and in below-grade waterproofing to help prevent water intrusion.

Hot-applied rubberized asphalt provides a seamless, monolithic waterproofing layer that's ideal for larger applications with concrete substrate. It can be a cost-effective solution for vegetated roofs, amenity decks, and split slab applications.

Factors to Consider When Specifying Waterproofing Systems

When selecting a waterproofing system, it's crucial to consider several factors to help ensure the system performs as expected over the long term. For example, hydrostatic pressure, soil conditions, and water presence must be evaluated when specifying a waterproofing system. These factors influence the right type of membrane and application method for a project.

Waterproofing systems must also meet the building's performance and life cycle expectations. Damaged or non-functional waterproofing systems can be difficult to replace during the building's life. Additionally, waterproofing must be compatible with the applications it is directly in contact with, including drainage, green roofs, and traffic surfaces.

Installation and Maintenance Best Practices

To help ensure the membrane system performs as expected, closely following the manufacturer's installation guidelines and specifications is essential. This includes proper surface preparation (cleaning and priming), careful handling, and attention to detail with corners, seams, and penetrations.

Regular inspections can help identify and address potential issues early, such as cracks, blisters, or areas of water infiltration. Routine maintenance, including cleaning and resealing joints, can help extend the life cycle of the waterproofing system and reduce the risk of costly repairs.

The Benefits of High-Quality Waterproofing Membranes

Properly installed waterproofing systems can provide lasting protection against water infiltration, safeguarding the building's structure against damage. Water damage prevention also helps reduce the need for repairs and replacements, leading to lower life cycle costs. Some waterproofing membranes—particularly those used in green roofs—can contribute to a building's sustainability efforts by enhancing energy efficiency and stormwater management.

While selecting the right waterproofing membrane is crucial for long-term protection, choosing the right sealant can further enhance the durability and performance of the commercial roof. Sealants can be used to address gaps, seams, and penetrations, providing a robust waterproof barrier that complements the overall roofing system. By combining high-quality membranes and sealants, the building can be better protected against water infiltration and environmental stress.

Ultimately, the proper specification, installation, and maintenance of waterproofing membranes are crucial for any building project, especially when addressing areas exposed to pedestrian or vehicular traffic or overburden conditions. By understanding the distinctions between waterproofing and roofing membranes, selecting the appropriate system for each application, and maintaining these systems as needed, consultants, contractors, and architects can contribute to their buildings' longevity and performance.