Terapro 250 Concrete Protection & Surfacing for Vehicular Traffic Areas

Terapro 250 is a surfacing layer used for vehicular applications. It provides PMMA waterproofing performance and added concrete protection for parking decks and ramps, vehicular areas, and over unoccupied space.

ADVANTAGES

- Fast-curing - ready for traffic in approximately 2 hours1 when installed properly

- Provides protection against typical vehicular fluids2

- Tested in accordance with ASTM E303 to provide skid resistance

- UV stable and can be applied in temperatures as low as 32°F

USES

- Suitable for parking decks, ramps, vehicular areas, and over unoccupied space.

2Siplast warranties and guarantees do not provide coverage against traffic, physical damage/impact/abuse or exposure to chemicals and other environmental contaminants. Refer to siplast.com for more information on warranty and guarantee coverage and restrictions.

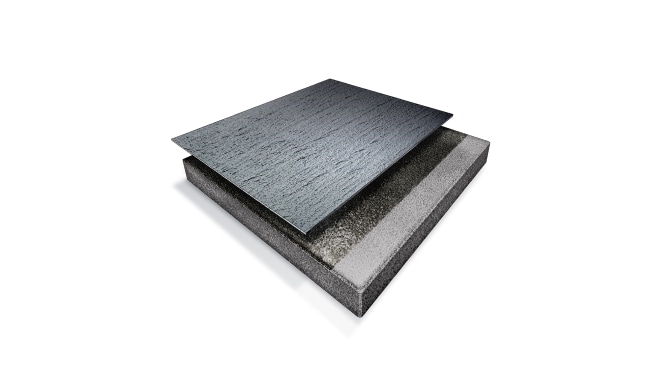

About Terapro 250 Resin / Aggregate

The PMMA properties of Terapro 250 allow it to achieve both a bond to the substrate and an interlaminar bond. This tenacious adhesion results in improved resistance to disbonding under the loads imposed by heavy vehicular traffic. Terapro 250’s bond strength, together with the tough crystal quartz surfacing, offers exceptional durability. The completed high-mil thickness application is monolithic and seamless. The liquid-applied, layered application consists of one coat of primer, a filled waterproofing layer, a hard-wearing quartz surfacing, and a durable pigmented finish layer. Each layer of the system consists of a catalyzed PMMA resin..

The convenience of Terapro 250 aggregate, color, and resin in one package allows you to catalyze, mix, and go. This ability combined with the fast-curing properties of PMMA make Terapro 250 application extremely efficient.

Contact Siplast for specific information on approved product uses.

Featured Benefits

Terapro 250 - Beige and Brown

Terapro 250 - Gray

Installation

Application

Refer to the applicable Siplast Technical or Installers Guide for detailed application information, including application/coverage rates. The product must be catalyzed before use using Pro Catalyst Liquid or Powder. See mixing charts that are supplied with Pro Catalyst products.

Application and coverage rates may vary depending upon the profile and absorbency of substrate. Refer to Siplast Installers Guide for specific applications.

Storage and Handling

Store indoors in a well-ventilated, cool, dry area away from heat, open fire, ignition sources, direct sunlight, oxidizing agents, strong acids, and strong alkalis. Do not store below 32°F (0°C). Products may auto-polymerize at temperatures greater than 140°F (60°C). Store jobsite materials on pallets in a shaded, well-ventilated area. Cover unshaded areas with reflective tarp that allows air circulation. Standard shelf life is 12 months; product life is reduced when stored at temperatures above 77°F (25°C).

See product packaging and the Safety Data Sheet for specific information on the safe handling of this product.

Packaging

25-kg Resealable Metal Drum

Weight Per Pail: 55.11 lb (25 kg)

Pails Per Pallet: 36

Pro Catalyst

Recommended Articles

-

Terapro Vehicular Waterproofing and Surfacing Systems

Siplast offers a variety of Terapro PMMA formulations and surfacing options to enable you to select the Terapro System that best matches your project requirements.Explore Vehicular Systems -

Terapro Concrete Protection Systems

A refreshed look with added concrete protection – that’s the benefit of Terapro 220 and Terapro 250. The liquid-applied, pigmented PMMA resin/aggregate blend is used as pedestrian and vehicular surface protection with anti-skid properties in accordance with ASTM E-303.Explore Concrete Systems